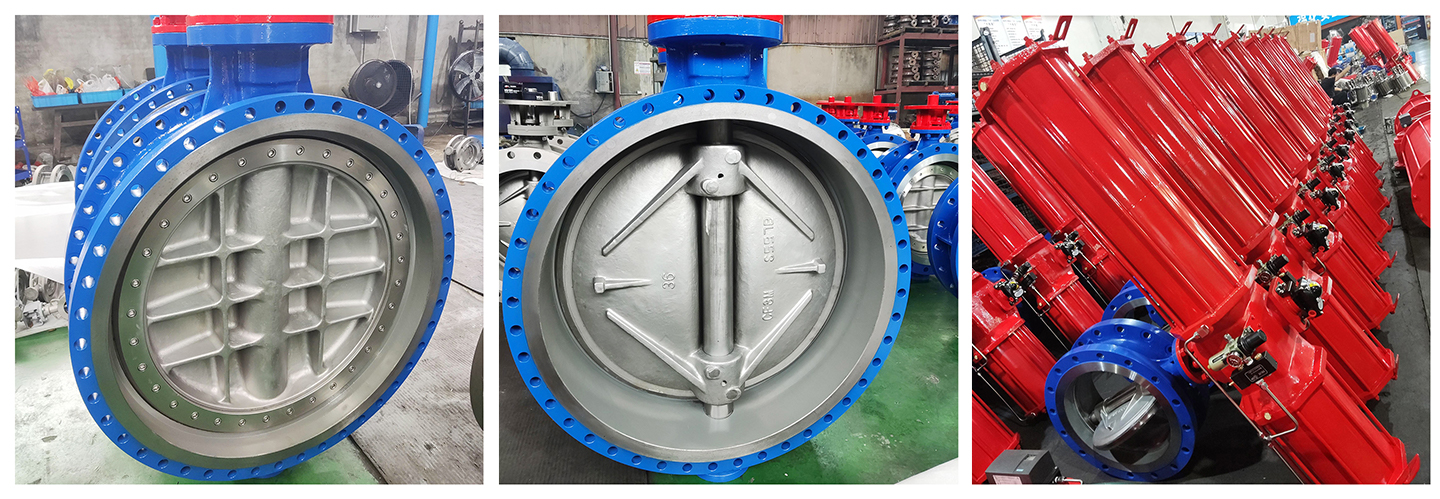

DN900 Pneumatic Triple Eccentric Hard Seal Butterfly Valve

Size: DN80~DN3200

Pressure Rating: PN10, PN16, CL150, JIS 5K/10K

Material: SS304, SS316

Design Standard: EN 593, MSS SP67, API 609, BS5155

Inspection Standard: API 598, ISO 5208, EN 12266

Application medium: Water, Steam and Oil

Application Temperature: -29 °C to 425°C

Applied projects: Chemical electric power/ Textile/ Food/ Medicine/ Paper

Send E-mail:info@wsdvalve.com Mobile: +86-173197327665

The triple eccentric hard seal butterfly valve is an industrial valve whose key features lie in the “triple eccentric” design in the structure and the hard seal material used. Compared with traditional soft-sealed butterfly valves, the sealing surface material of hard-sealed butterfly valves is usually metal or carbide, which makes them perform well in harsh working conditions such as high temperature, high pressure, and strong corrosion. The triple eccentric design effectively reduces the wear of the sealing surface when the valve is opened and closed, thereby extending the service life of the valve.

Triple-eccentric butterfly valves are widely used in petroleum, chemical, energy, metallurgy and other industries. Their structure and design allow them to maintain excellent sealing and stability in extreme environments. Triple eccentric butterfly valves are usually used in situations where reliable sealing and durability are required, such as high temperature and high pressure steam pipelines, corrosive media transportation and other fields.

WESDOM valves are installed all over Asia, Africa continent, the Middle East, and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability, and quality worldwide.

Why choose us!

-

WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards

for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

W -

The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

E -

Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

S -

One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

D -

WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

O -

WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

M

Quality Control Process

Standard Test

Factory Tour

WESDOM GROUP consists of 5 factories and 4 overseas branches. The five factories are mainly located in Tianjin, Hebei, Shandong, Lianyungang and Wenzhou. The four foreign branches are located in Tanzania, Zambia, Kenya and Indonesia.

| DN | Main ouler size | Main connection size | |||||||||||||||

| 0.6Mpa | 1.0Mpa | 1.6Mpa | |||||||||||||||

| L | H | H1 | A | B | D | D1 | D2 | n-d | D | D1 | D2 | n-d | D | D1 | D2 | n-d | |

| 50 | 108 | 825 | 306 | 80 | 80 | 140 | 110 | 88 | 4-14 | 165 | 125 | 99 | 4-18 | 165 | 125 | 99 | 4-18 |

| 65 | 112 | 925 | 321 | 80 | 80 | 160 | 130 | 108 | 4-14 | 195 | 145 | 118 | 4-18 | 185 | 145 | 118 | 4-18 |

| 80 | 114 | 100 | 346 | 80 | 80 | 190 | 150 | 124 | 4-18 | 200 | 160 | 132 | 8-18 | 200 | 160 | 132 | 8-18 |

| 100 | 127 | 110 | 37 | 95 | 95 | 210 | 170 | 144 | 4-18 | 220 | 180 | 156 | 8-18 | 220 | 180 | 156 | 8-18 |

| 125 | 140 | 125 | 411 | 95 | 95 | 240 | 200 | 174 | 8-18 | 250 | 210 | 184 | 8-18 | 250 | 210 | 184 | 8-18 |

| 150 | 140 | 1425 | 447 | 95 | 95 | 265 | 225 | 199 | 8-18 | 285 | 240 | 211 | 8-22 | 2B5 | 240 | 211 | 8-2 |

| 200 | 152 | 170 | 607 | 190 | 300 | 320 | 280 | 254 | 8-18 | 340 | 295 | 266 | 8-22 | 340 | 296 | 266 | 12-22 |

| 260 | 165 | 1925 | 688 | 190 | 308 | 376 | 335 | 309 | 12-18 | 396 | 350 | 319 | 12-22 | 405 | 355 | 319 | 12-26 |

| 300 | 178 | 2225 | 742 | 190 | 308 | 440 | 395 | 363 | 12-22 | 445 | 400 | 370 | 12-22 | 480 | 410 | 370 | 12-26 |

| 350 | 190 | 2525 | 797 | 190 | 30B | 490 | 445 | 413 | 12-22 | 505 | 460 | 429 | 16-22 | 520 | 470 | 429 | 16-26 |

| 400 | 216 | 2825 | 930 | 270 | 486 | 540 | 495 | 463 | 16-22 | 565 | 515 | 480 | 16-26 | 580 | 525 | 480 | 16-30 |

| 450 | 222 | 3075 | 975 | 270 | 486 | 566 | 550 | 518 | 16-22 | 615 | 565 | 530 | 20-26 | 640 | 585 | 548 | 20-30 |

| 500 | 229 | 335 | 1065 | 270 | 486 | 645 | 600 | 568 | 20-22 | 670 | 620 | 6R2 | 20-26 | 715 | 650 | 609 | 20-33 |

| 600 | 267 | 390 | 1225 | 457 | 625 | 755 | 705 | 667 | 20-26 | 780 | 725 | 682 | 20-30 | 840 | 770 | 720 | 20-36 |

| 700 | 292 | 4475 | 1343 | 457 | 625 | 860 | 810 | 772 | 24-26 | 895 | 840 | 794 | 24-30 | 910 | 840 | 794 | 24-36 |

| 800 | 318 | 5075 | 1436 | 457 | 625 | 975 | 920 | 878 | 24-30 | 1015 | 950 | 901 | 24-33 | 1025 | 950 | 901 | 24-39 |

| 900 | 330 | 5575 | 1616 | 598 | 853 | 1075 | 1020 | 978 | 24-30 | 115 | 1050 | 1001 | 28-33 | 1125 | 1050 | 1001 | 28-39 |

| 1000 | 410 | 615 | 1711 | 598 | 853 | 1175 | 1120 | 1078 | 28-30 | 1230 | 1160 | 1112 | 28-36 | 1255 | 1170 | 112 | 28-42 |

| 1200 | 470 | 7275 | 1971 | 598 | 853 | 1405 | 1340 | 1295 | 32-33 | 1455 | 1380 | 1328 | 32-39 | 1485 | 1380 | 1328 | 32-48 |

| 1400 | 530 | 8375 | 2218 | 860 | 1345 | 1630 | 1560 | 1510 | 36-36 | 1675 | 1590 | 1530 | 36 -42 | 16865 | 1590 | 1530 | 36-48 |

| 1600 | 600 | 957.5 | 2578 | 880 | 1345 | 1800 | 1760 | 1710 | 40-36 | 1915 | 1820 | 1750 | 40-48 | 1990 | 1820 | 1760 | 40-56 |

| 1800 | 670 | 1067.5 | 2689 | 880 | 1345 | 2045 | 1970 | 1918 | 44-39 | 2115 | 2020 | 1950 | 4448 | 2130 | 2020 | 1960 | 44-56 |

| 2000 | 760 | 1162.5 | 3022 | 952 | 1592 | 2265 | 2180 | 2125 | 48-42 | 2325 | 2230 | 2150 | 48-48 | 2345 | 2230 | 2150 | 48-82 |

Advantages of double eccentric butterfly valve!

-

Small valve opening and closing torque

Due to the existence of eccentricity, when the valve is closed, the sealing surface is a gradual entry and exit process, thus reducing the mechanical wear and extrusion between the sealing surfaces.

W -

The sealing ratio pressure can be adjusted

When the valve is used for a period of time or loosened during transportation, it can be pressed to ensure the sealing requirements.

E -

Sealing ring can be replaced on site

The rubber sealing ring is mounted on the butterfly plate and can be replaced in-line.

S -

Long service life

The seal ring and the valve seat contact is anastomosis seal, there is no mechanical wear and extrusion, so the seal ring of double eccentric butterfly valve has a longer service life.

D -

Using conditions

Suitable for large installations and pipelines in drainage, heating, and gas systems as well as chemical power generation and metallurgy industries.

O -

With two-way sealing performance

With two-way sealing performance, especially suitable for media with both positive flow requirements and reverse flow requirements of the working conditions (need to be specified when ordering).

M

What are the characteristics and biggest advantages of triple eccentric hard seal butterfly valve?

Triple eccentric hard seal butterfly valve has shown many advantages in the industrial field with its unique design and hard material.

Here are its main features and biggest advantages:

Friction-free seal:

Thanks to the triple-eccentric design, the triple-eccentric butterfly valve has almost no friction when opening and closing. This not only extends the life of the sealing surface, but also improves the sealing performance of the valve and avoids common seal failure problems.

High temperature and high pressure resistance:

The sealing material of hard-sealed butterfly valves is usually metal or carbide, which allows it to withstand extreme high temperature and high pressure environments. In contrast, soft-sealed butterfly valves may fail due to aging or deformation of the sealing material at high temperatures, while hard-sealed butterfly valves can continue to work stably under harsh conditions.

Strong corrosion resistance:

Since the sealing material of the triple eccentric butterfly valve can be corrosion-resistant metal or alloy, it is suitable for handling corrosive media, such as acids, alkalis and other chemical substances. Compared with soft-sealing butterfly valves, it is more durable in corrosive media.

Long service life:

The triple eccentric butterfly valve will not fail due to wear when sealing, so it can still maintain a long service life even under frequent opening and closing operations. This is especially important for systems requiring high frequency operation.

High sealing reliability:

The triple eccentric design allows the sealing surfaces of the butterfly plate to automatically come together when closing, achieving a self-locking function and ensuring no leakage of media. This design greatly improves the sealing reliability of the valve and is especially suitable for working conditions requiring zero leakage.

Turkey Project Case

Project Name:

Turkey plant project

End User:

International Investment Company

Supply Products:

From DN300 to DN900 Electric Butterfly Valves

Contract Amount:

USD 370,000

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.