According to the structure, ball valves can be divided into: floating ball valves, fixed ball valves, V-shaped ball valves, three-way ball valves, stainless steel ball valves, cast steel ball valves, forged steel ball valves, pneumatic ball valves, electric ball valves, welded ball valves, etc. The following mainly introduces the commonly used floating ball valves. Ball valves and fixed ball valves.

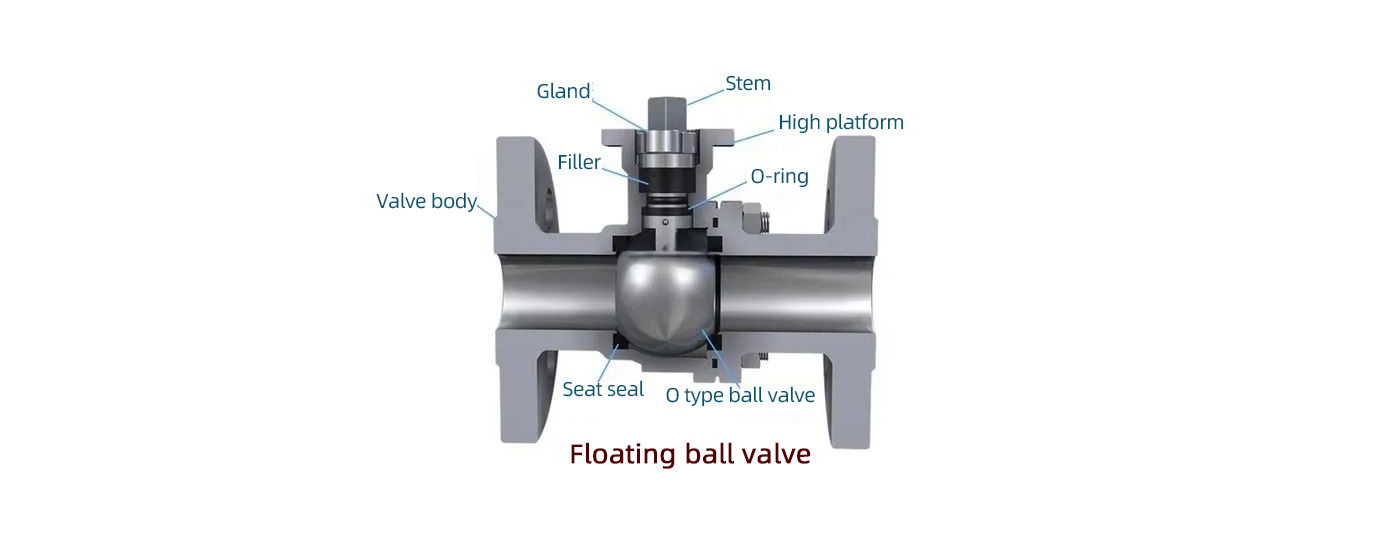

The floating ball valve squeezes the middle ball core through the valve seat sealing rings on both sides of the inlet and outlet. The ball of the floating ball valve is floating. Under the action of medium pressure, the ball can produce a certain displacement and press against the sealing surface of the outlet end to ensure the sealing of the outlet end.

When the valve stem is driven to rotate, the valve stem drives the ball core to rotate, thereby realizing the opening and closing action of the ball valve. When the ball core is closed, the semicircle at the top of the valve stem is in the same direction as the semicircular groove of the ball core. Under the action of medium pressure, the ball core moves toward the outlet, so it is called a floating ball valve.

The floating ball valve has a simple structure and good sealing performance, but all the load of the working medium on the ball is transferred to the outlet sealing ring. Therefore, it is necessary to consider whether the sealing ring material can withstand the working load of the ball medium. When subjected to higher pressure impact , the sphere may shift. This structure is generally used for medium and low pressure ball valves.

The main features of ball valves are compact structure, reliable sealing, simple structure, and easy maintenance. The sealing surface and spherical surface are always in a closed state and are not easily eroded by the medium. They are easy to operate and maintain. They are suitable for general work such as water, solvents, acids, and natural gas. media, and is also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene, etc., and is widely used in various industries. The ball valve body can be integral or combined.

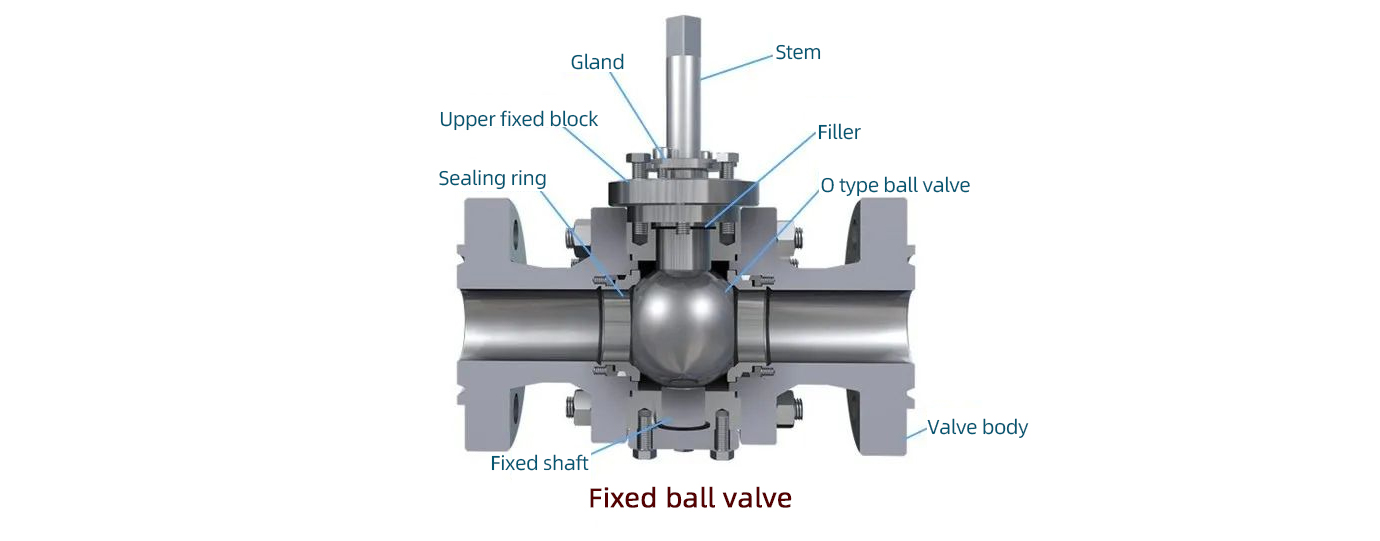

Fixed ball valves also have two valve seat seals at the inlet and outlet. The middle ball core passes through the upper and lower valve stems and is fixed with the valve body. The switching action of the ball core can only be driven by the rotation of the valve stem. It cannot move toward the outlet like a floating ball valve because the upper and lower stems limit the movement of the ball core. So it is called fixed ball valve.

The ball of the fixed ball valve is fixed and does not move when pressed. Fixed ball and ball valves all have floating valve seats. After being subjected to medium pressure, the valve seat moves, causing the sealing ring to press tightly on the ball to ensure sealing.

Bearings are usually installed on the upper and lower shafts of the ball, with small operating torque, and are suitable for high-pressure and large-diameter valves.

Features of floating and fixed ball valves:

Features of floating ball:

Mostly used for low pressure and small diameter. When the pressure is too high, the medium pushing the ball core will crush the outlet valve seat and increase the ball valve torque.

Features of fixed balls:

Mostly used for high pressure and large diameter. The structure of the valve seat pressing the ball core can reduce the valve seat sealing pressure. Reduce ball valve torque. Compared with the rotation dead zone of the floating ball structure, the error is smaller.

Pressure relief methods of floating and fixed ball valves:

The floating ball valve releases pressure from the rear seat. The ball is movable and the seat is fixed. Under working conditions such as LNG and hydrogen peroxide, there will be a 3 mm opening on the upstream side of the ball. In the closed state, the overpressure in the middle cavity will be released to the upstream side. For pressing! The fixed ball is used to relieve pressure from the valve seat. The ball is fixed and the valve seat is movable.

Application occasions of floating and fixed ball valves:

Floating ball valves are widely used in:

Chemical, petroleum, natural gas, metallurgy and other industries, as well as long-distance natural gas pipelines containing hydrogen sulfide media, many impurities, and serious corrosion

Fixed ball valves are widely used in:

Dosing devices/equipment, automatic control systems in industrial sectors such as papermaking, petrochemical, chemical, metallurgy, electric power, environmental protection, petroleum, light industry, etc.

In addition, generally choose a fixed structure for the bodywork if it is above 3″ (industry regulations), choose a floating one if it is 1″, and there are both floating and fixed ones if it is 2″.