-

WEIZIDOM Eccentric Metal-Seated Butterfly Valve Selection & Installation Guide

The eccentric metal-seated butterfly valve is a high-performance valve that utilizes an eccentric structural design combined with a metal-to-metal sealing pair. It is suitable for medium to high-pressure, high-temperature, and high-sealing-requirement working conditions. The sealing form typically involves metal-to-metal contact (e.g., stainless steel + hard alloy), or metal to flexible alloy coating, offering excellent wear and temperature resistance.

READ MORE14

2025.05

-

How to Select the Right Butterfly Valve?

A butterfly valve is a type of valve commonly used in fluid pipelines to isolate, regulate, or throttle the flow of media. Due to its simple structure, compact size, lightweight design, and fast actuation, it is widely applied in industries such as waterworks, chemical processing, petroleum, power generation, food and beverage, and pharmaceuticals.

READ MORE06

2025.05

-

The Ultimate Guide to Metal-Seated Gate Valves

A hard-sealed gate valve is a type of valve that uses metal or other hard materials for its sealing surfaces. It is primarily used in pipeline systems involving high temperature, high pressure, or media containing particulates or corrosive substances.

READ MORE27

2025.04

-

Is Soft-Sealed Gate Valve Prone to Leakage?

The sealing performance of soft-sealed gate valves relies on elastic materials (e.g., rubber, PTFE). Over time, these materials may degrade due to temperature, media, or prolonged use, leading to hardening, cracking, or detachment, which compromises sealing and causes leakage.

READ MORE18

2025.04

-

The Irreplaceable Role of Hard-Sealed Gate Valves in High-Pressure Environments

In the oil and gas industry, valves are the core components of fluid control systems, directly impacting operational safety and system stability. With the increasing depth of extraction and the extension of transportation distances, valves are required to perform under more demanding conditions, including high pressure, extreme temperatures, and corrosive media.

READ MORE11

2025.04

-

How to Select Valves in the Chemical Industry? Hard-Seal vs. Soft-Seal Gate Valves

Hard-seal valves are suited for extreme conditions (high temp/pressure, corrosive/abrasive media), offering long-term reliability. Soft-seal valves provide cost-effective sealing in mild environments. Select based on operational demands, media properties, and budget to optimize safety, reliability, and cost-efficiency.

READ MORE03

2025.04

-

The corrosion resistance of stainless steel gate valves is so good?

Gate valve is a general term and can be used in various positions in pipelines according to needs. For example, it can be used as a water valve in domestic water supply, fire protection systems and industrial water supply systems to control water flow, water temperature, etc.

READ MORE30

2025.03

-

What are the installation and contraindications for valves such as gate valves and butterfly valves?

During the installation process of gate valves, butterfly valves and other valves, the quality of the installation will directly affect the normal operation in the future, so you must pay attention to it. So, how to install gate valves and butterfly valves? Five key points for installing the five major valves: 1. Direction and location Many valves are directional: For example, stop valves, throttle valves, pressure reducing valves, check valves, etc., if installed upside down, will affect the use effect and life (such as throttle valves), or will not work at all (such as pressure reducing valves), or even Causing hazards (e.g. check valves). Generally, valves have direction marks on the valve body. If not, it should be correctly identified based on the working principle of the valve. The valve cavity of the stop valve is asymmetrical from left to right, and the fluid must pass through the valve port from bottom to top. In this way, the fluid resistance is small (determined by the shape), and it is labor-saving to open (because the medium pressure is upward). After closing, the medium does not press the packing, which is convenient for maintenance. , this is why the stop valve cannot...

READ MORE23

2025.03

-

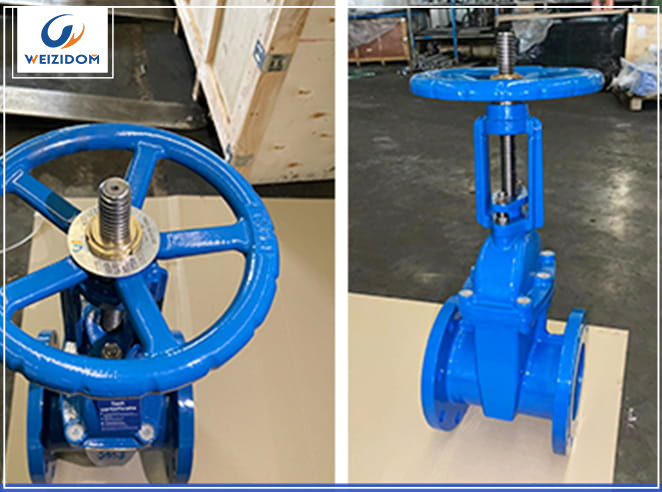

What is rising stem gate valve?

The opening and closing parts of the rising stem gate valve is the gate plate, and the direction of motion of the gate plate is perpendicular to the fluid direction, and the open rod gate valve can only be fully opened and closed, and can not be adjusted and throttling.

READ MORE17

2025.03

-

Understanding the Distinction: Wafer Butterfly Valve vs. Flange Butterfly Valve

In the realm of fluid control systems, butterfly valves play a crucial role in regulating flow. Among the varieties of butterfly valves available, the wafer butterfly valve stands out for its compact design and versatile application. The term "butterfly valve" refers to a valve that uses a circular disc or vane to regulate flow by pivoting on an axis perpendicular to the direction of flow.

READ MORE03

2025.03

-

What incorrect operations can cause butterfly valves to leak?

As an important fluid control component, butterfly valves are widely used in pipeline systems. However, the leakage problem of butterfly valves is often a headache, especially when it is operated incorrectly or improperly maintained, the risk of leakage will increase significantly.

READ MORE25

2025.02

-

How should knife gate valves be maintained?

Knife gate valves are used to shut off a variety of solid-containing media applications, including oil sand slurries, pulp feedstocks, mines, wastewater treatment, power stations, and more. Routine maintenance and repairs are also very important to ensure normal use.

READ MORE19

2025.02