1. The valve adopts pressure self-tightening seal or valve body and bonnet gasket seal structure, which is trustworthy! It is safe and reliable to use.

2. The valve disc adopts a double gate with a universal top structure in the middle, which can automatically adjust the fit between the valve disc and the sealing surface of the valve seat to ensure the sealing of the valve. At the same time, this structure is convenient to maintain, save costs, and has better valve disc interchangeability.

3. The sealing surface of valve disc and valve seat is made of cobalt-chromium-tungsten cemented carbide by plasma spray welding. The sealing surface has high hardness, abrasion resistance, abrasion resistance and long service life.

4. The valve stem is made of nitriding steel with surface nitriding treatment, high hardness, scratch resistance, corrosion resistance and long service life.

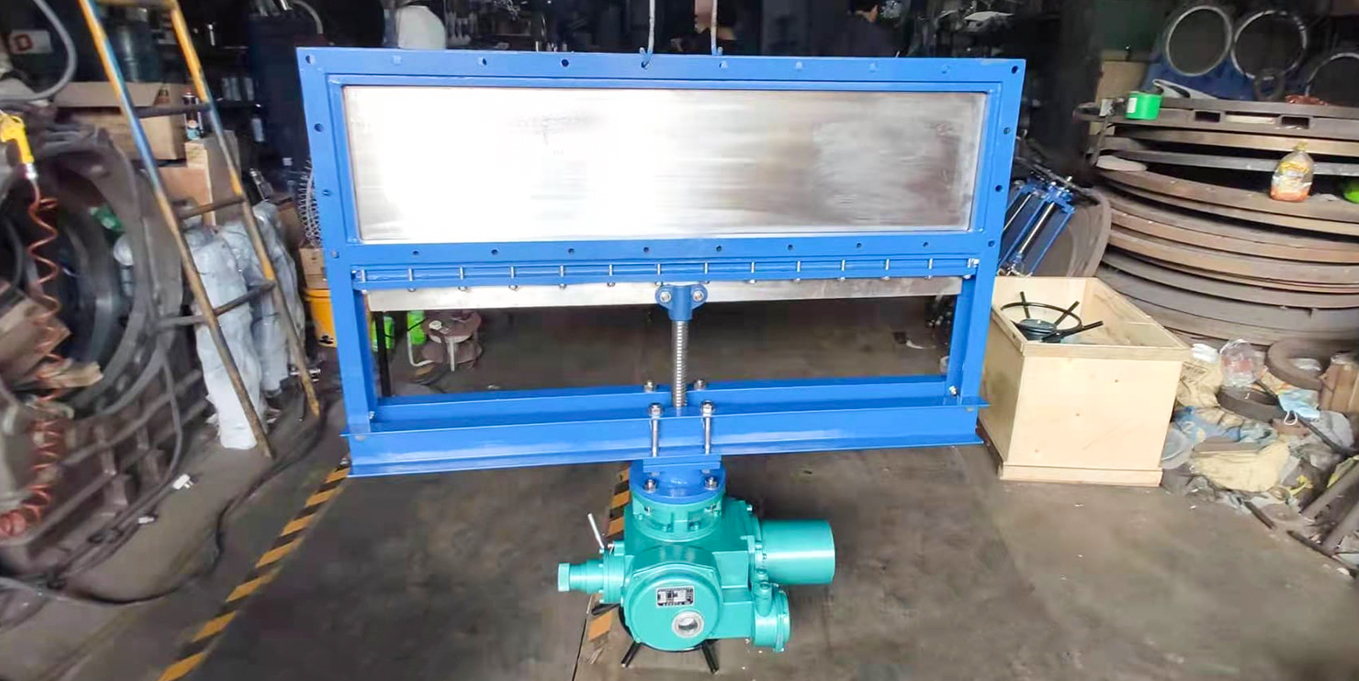

5. The electric device is equipped with a torque control mechanism, an on-site operating mechanism, and a hand and electric switching mechanism. In addition to local operation, remote operation, PLC control, 4-20mA current input and output intelligent control, etc. can also be carried out.

6. The manual valve is opened by the manual mechanism or the hand wheel upon impact. Reduce valve operating force.

7. The valve can be installed in any position of the pipeline, and the carbon steel or alloy steel valve can be selected according to the temperature of the medium and the medium.

8. When installing and debugging for the first time, the valve must be manually opened to about half of the position, so as to avoid damage to the valve or electrical equipment due to the reverse connection of the motor phase sequence.